The Facts About Premier Aluminum Llc Revealed

The Facts About Premier Aluminum Llc Revealed

Blog Article

6 Simple Techniques For Premier Aluminum Llc

Table of ContentsIndicators on Premier Aluminum Llc You Should KnowGet This Report about Premier Aluminum LlcIndicators on Premier Aluminum Llc You Need To KnowThe Of Premier Aluminum Llc

(https://www.intensedebate.com/people/premieraluminum)Typically, a purchaser's main duty was to find professional and receptive suppliers. In many cases, buyers assumed that any kind of distributor ready to contractually satisfy the purchase requirement was certified. However, using inexpensive and unqualified vendors can create high quality issues, and wasted time and cash in the future. To aid you with the procedure, right here are some things to think about when choosing the ideal metal casting supplier.

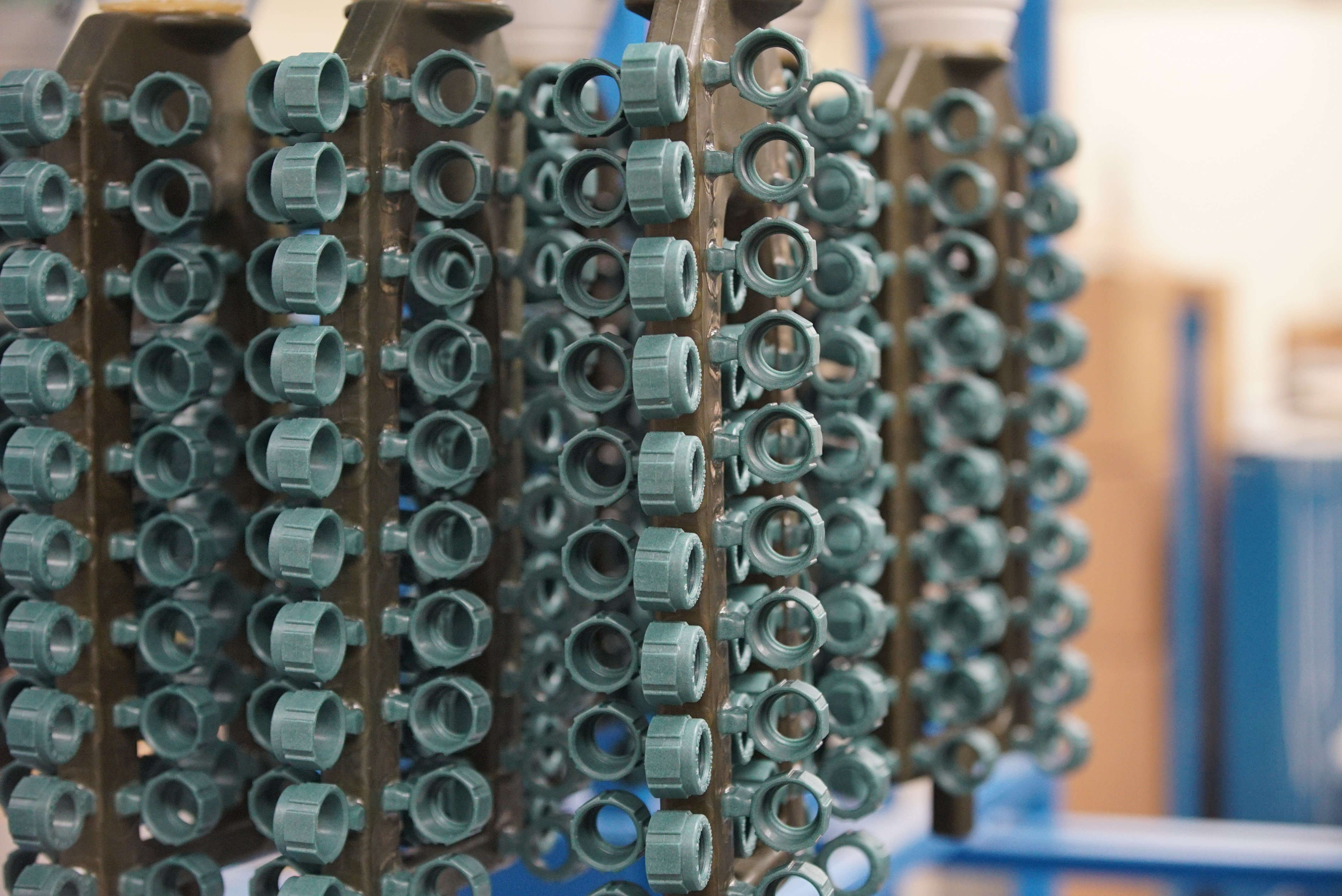

A firm that only utilizes the investment casting process will certainly try to offer you on why that process is best for your application (Foundry near me). But what if using the sand casting procedure is best for you and your requirements? Instead, try to find a vendor that supplies a range of casting processes so the most effective option for YOU is picked

If collaborating with a solitary resource for every one of your casting needs is necessary to you, the vendor requires to be diverse in its capacities. When integrated with various other integrated capabilities, this can help simplify and press the supply base. When picking the best casting provider, cautious factor to consider ought to be provided to top quality, service, and price.

The 8-Minute Rule for Premier Aluminum Llc

Buyers increasingly choose spreading providers who have machining abilities. If the casting vendor discovers a problem during machining, the trouble is dealt with much faster with no disagreement over whose mistake it is.

What do you require from your spreading distributor? Are you looking for somebody to simply deliver a steel component to your doorstep or do you require extra?

Some shops are minimal or specialized. Make sure the supplier can satisfy all your material or alloy needs to get rid of the demand for several providers.

7 Easy Facts About Premier Aluminum Llc Shown

Research study the supplier's website. Talk to a sales rep or service partner. Ask a whole lot of questions. See their facility. Get an understanding of what they can do for you and if you can see on your own developing a solid, common partnership with them.

Light weight aluminum is likewise light-weight and has great corrosion resistance, making it optimal for applications where weight and longevity are essential variables. In addition, light weight aluminum spreading is a cost-efficient approach of production, as it requires much less energy and sources than various other approaches. Iron casting, on the other Check Out Your URL hand, includes pouring molten iron right into a mold to produce a desired shape.

Premier Aluminum Llc for Dummies

Iron spreading is additionally able to hold up against high temperatures, making it ideal for usage in applications such as engine components and commercial equipment. Nonetheless, iron casting can be much more costly than light weight aluminum casting as a result of the higher expense of resources and the power called for to thaw the iron. When deciding in between aluminum spreading and iron spreading, it is necessary to take into consideration the particular requirements of the application.

In verdict, both aluminum spreading and iron casting have their very own distinct advantages and downsides. There are three sub-processes that fall under the group of die casting: gravity die casting (or long-term mold casting), low-pressure die casting and high-pressure die casting. To obtain to the finished product, there are three main alloys used as die spreading material to pick from: zinc, light weight aluminum and magnesium. Report this page